2022-01-01

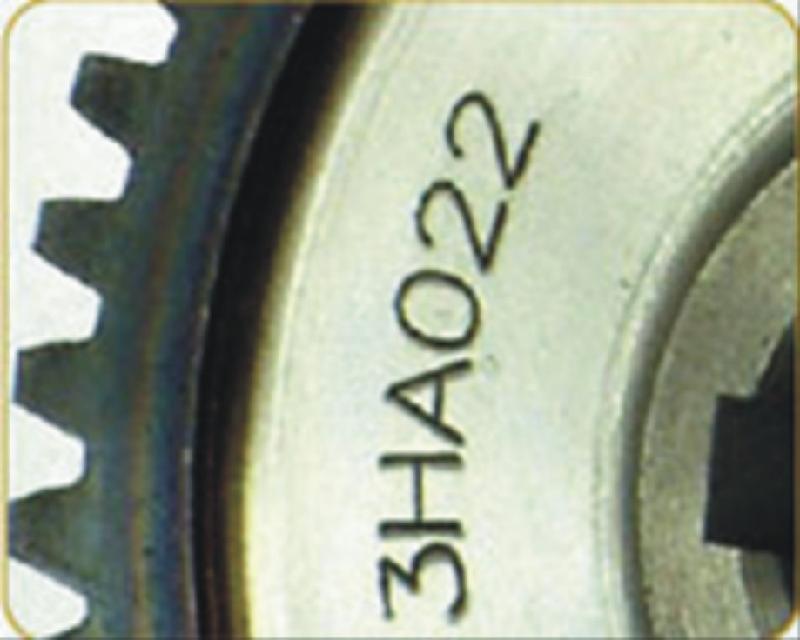

A car is composed of numerous and various auto parts. To distinguish, identify and manage complex and diverse parts, it is necessary to identify information on its surface markings.

Automobile and auto parts manufacturers pay more and more attention to details and perfection. Laser marking machines occupy a place in the field of auto parts by virtue of the insurmountable advantages of traditional processing methods.

In the field of auto parts processing, laser marking machines are mainly used for marking information such as QR code, barcode, clear code, production date, serial number, Logo, pattern, certification mark, warning mark, etc. Including high-quality marking of automobile wheel arcs, exhaust pipes, engine blocks, pistons, crankshafts, audio transmission buttons, labels (nameplates) and many other accessories.

The processing principle of the laser marking machine is to use a high-energy laser beam to irradiate the surface of the auto parts, the light energy instantly becomes heat energy, and the surface of the parts evaporates rapidly, so as to engrave any required text and graphics as a permanent Anti-counterfeiting identification mark.

The advantages of laser marking machine:

High precision: The laser processing precision can reach within millimeters, which can realize ultra-fine graphic marking.

Wide range of materials: The laser marking machine is suitable for most auto parts materials, including metal or non-metal.

High efficiency: The laser processing speed is fast, and the use of automatic assembly lines and robots can greatly improve production efficiency.

Good effect: The laser can complete the graphic marking of accessories with different depths, and realize the effects of laser whitening, laser blackening, and laser color marking.